Roll benders (aka, angle rolls) are machines used to roll out shapes of materials such as bars, rods, pipes, tubing and other solid structures. Our angle rolls are used for a variety of applications that form profiles of rectangular tubing, round tubing pipes and more. These high efficiency angle roll benders are composed of high quality grade steel frames that are designed to withstand high resistance and meet the demands of large dimension parts.

Our selection includes equipment that has been engineered with robust designs and uses the most advanced technology in the industry. Many of our machines are double pump hydraulic powered with the capacity to operate horizontal and vertically with versatile roll adjustments. We offer a variety of section bending machines with that have the ability to handle wide flat rolls, low wall thickness and other specific needs. Our machines are specialized for your angle roll and bending needs and also provide you with minimal upkeep and maintenance.

Wow, was there ever a machine that caused so much confusion as the common roll bender? What do you call it? Roll Bender, Profile Roll, Angle Roll, Section Roll, Ring Bender, Ring Roll Bender, we could go on. Suffice it to say, you get the idea. We had a salesman who created an angle roll comparison sheet of 17 different manufacturers some time back, and he reported that he received a good lesson on nomenclature during the process. Apparently the top four or five terms or names used to describe the angle roll are very much regional. If you’re from the Northeastern U.S. you call it one thing and someone from the Northwest might call it something else — it just depends on what you're used to and where you come from.

In all fairness to the roll bender/angle roll, as you look about the modern fabrication company you’re likely to see a machine that takes the title of the “most unique” machine tool in the shop. That machine is, of course, the ironworker. It’s true: you would be hard-pressed to find a machine that does as much as an ironworker does, and performs that work as easily as it appears. (And while we're on the topic, please be sure to check out our Hydraulic Ironworkers page on this website.) An old machinist once remarked to one of our staff members, “If the ironworker is the Swiss Army knife of the fab shop, then the angle roll is the trenching tool.” We couldn’t have said it better ourselves. The line-up of Durma roll benders we carry sports some pretty faces, but don’t be fooled, these machines come ready to dance.

Durma roll benders owe their popularity to the fact that these metalworking marvels are made with the utmost care starting at the very base of the machine. The extremely solid and rigid base is cast and fabricated in the same production jig for all six sides of the machining process. The entire structure is created on the base using an exceptionally accurate 5-axis CNC milling machine. The end result is a solid base with the most accurate mounting and location holes possible. What this initial accuracy will get you is an easier assembly process as everything lines up better than when using older process methods. Less shimming of components because they didn’t fit exactly right is also a thing of the past. Bearings and shafts, so critical to the operation of a roll bending machine, are fixed in more accurate locations with greater concentricity, thereby reducing wear and tear on these components. Big electric motors are a hallmark of the Durma roll bending machines; that and big heavy hydraulic systems comprised of world renowned component manufacturers. Right down to the smallest machine in their line-up — the PBH-45 — Durma profile roll benders come standard with some version of side or lateral supports. On these roll benders all three rolls are powered, and along with that proficiency is the availability of powered lateral rolls. This type of arrangement allows for mid-bend corrections assisted by an L.E.D. readout. This combination of powered rolls all around means the operator now has a much-simplified procedure when setting up the roll for the first bend. All Durma hydraulic roll benders have a unique direct drive gearbox drive system which makes the most out of the horse power and torque coming from the main motor, which is also inverter-controlled. It is a little-known fact that most smaller Durma roll benders can be changed from a vertical operation by being literally laid on their backs and run in a horizontal plane! This method of operation opens up all kinds of possibilities and solves some possible issues with how to support larger thin body rings.

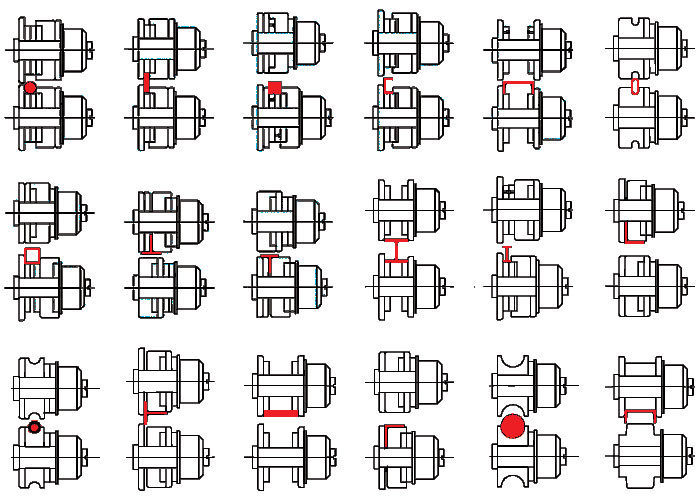

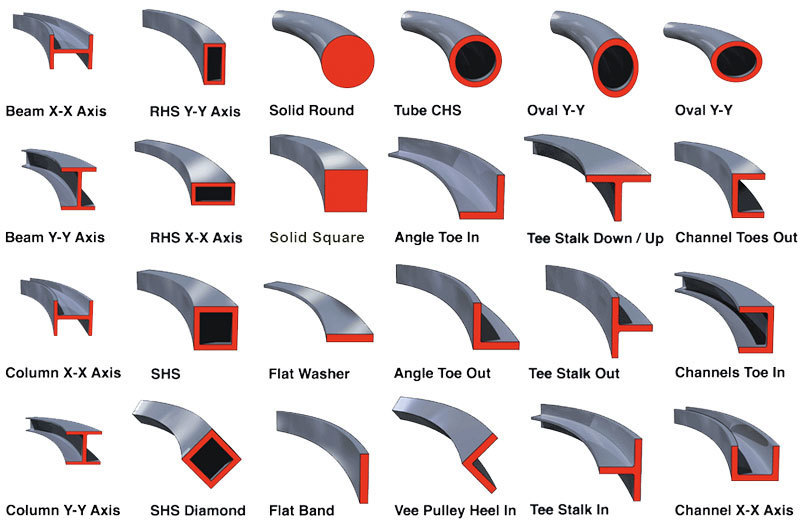

Productivity, a fleeting notion of what would improve output, obtainable by some, others not so much. For some shops, just being able to produce the part at all in-house is a victory. Keeping a part in-house, is that being productive? Fortunately, just about every shop in the fabrication industry should be able to afford some size of roll bender. Studying the width and breath of angle roll bending machine capabilities would keep a person busy all day long. In just the material types these benders can handle right out of the box could get one's head spinning. From the basic shapes (round, square, rectangle, extruded shape) an operator can also roll tubes, solids, rebar, angle iron and "T" iron. Durma profile rolls can do all of the aforementioned shapes and types of material in low carbon steel, medium to high carbon steel, stainless steel, aluminum, copper, cast iron, and just about anything else you can find that's made into a solid bar or tube. Size (and consequently price) start out very reasonable entry level. Durma's smallest machine, the PBM-30, will bend up to 1 ½” x 1 ½” x .125 square tubing; basically a manual roll bender, but with a motor to do the work. Midway up the chain of model sizes available, we look at the PBH-100 hydraulic roll bender, which has a capacity of 3” x 3” x ¼” square steel tubing. Way up the size chart is a machine model we refer to around here as just "BIG," the PBH-360, which has a capacity of 16” x 16” x 5/8 thick square steel tubing (and even bigger machines are available). The roll sections that come on our roll benders will do an incredible range of standard materials without the need to order any additional rolls. There is a chart that comes with the roll bender that shows 20 different set-up configurations, only four of which would require the need of any optional roll sections to run that specific material type.

There’s only one place in the Intermountain West where you can pick up a Durma roll bender and that is at Bud's Machine Tools based in Salt Lake City, Utah. Bud's has stayed in business by doing one thing very well. We service our customers just the way we would like to receive service when our own need arises. That master plan has served us well, and will continue to be our guiding star as we progress into future, always with our eyes on the prize, servicing our customers they way they deserve to be treated.Below are configurations of rolls (tooling) for rolling different profiles of metal on the Durma angle rolls sold by Bud's Machine Tools. All but the last four can done with the standard universal rolls that come with most machines (models PBH 60 through PBH 360).